38 6

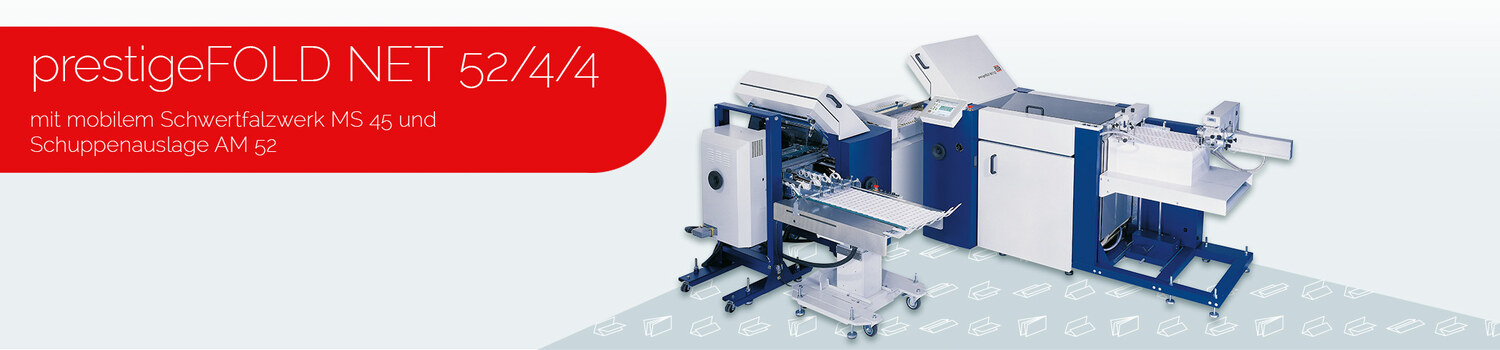

52 4 4 Schuppen

52 4 4 Schwert

52 6

Maximum output ensured.

Different demands are made on folding machines - depending on the particular type of job. High outputs, short set-up times, the best possible processing of multiple-ups or small folds are some of the criteria that are assessed differently from company to company.

However, one fact is always significant – folding machines must operate efficiently. But efficiency does not only mean that the folding process from the feeder to the delivery section has been optimized. Handling before and after folding is gaining increasing importance because the right technology in this place has a direct influence on the production costs of printed material.

In connection with the suitable delivery technology, pressing units offer a complex potential for increasing production. Various modules are available which are suited for the intended use.

For pressing of single sheets (small folds) in single or multiple ups

For pressing of single sheets in single or multiple ups

For pressing of single sheets in single or multiple ups

For pressing of single sheets in single or multiple ups

For pressing of single sheets in single or multiple ups

For pressing of prefoldings in single and multiple ups

For pressing of prefoldings in single and multiple ups